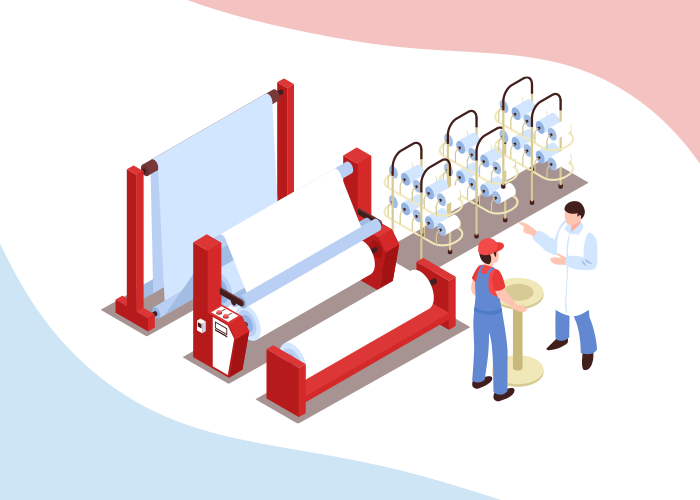

Abaris New Horizon: ERP Software For Geo-textile Manufacturing

Industry

The Geo-textile Manufacturing Industry has been growing exponentially, building up to a

highly competitive environment. With market players fighting for greater customer

attention & retention, agile and timely operations gained primary importance in an

attempt to fulfil latter’s expectations. In addition, leading companies are focusing on

how to introduce upgraded, latest products in the market before anyone else. This is

where a Geo-textile ERP Software can help your business.

A fitting ERP software for Geo-textile industry business helps eliminate the transfer

delays introduced between processes by smoothening out the internal procedure through

enhanced coordination and real-time communication throughout the functions

An ERP for Geo-textile Industry, designed by expert professionals, can give your

business the speed it needs to gain a competitive edge over other market players, while

you dedicate maximum efforts to product innovation and customer satisfaction.